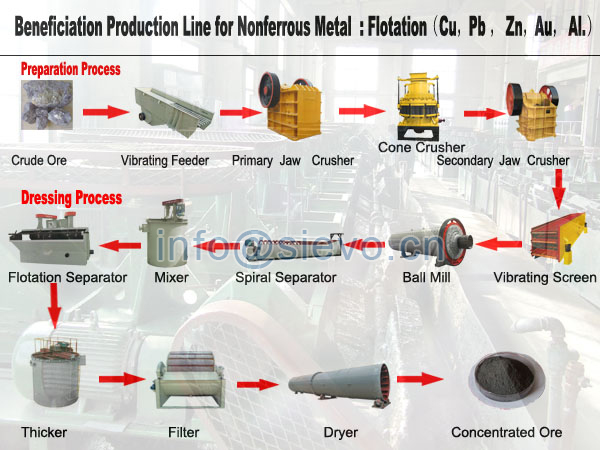

You are here : Home > Product > Flotation Machine/Flotation Machine Manufacturers/Flotation Machines/Flotation Mineral Processing

Flotation Machine

SF Flotation Machine Introduction:

SF series flotation machines are new products of our company, which introduced the international advanced technology, and borrowed ideas from decades of manufacturing experience. At present, it is already in absolute leading level at home and abroad. And the new structure of impeller is backwards inclined double impellers equipped with honeycomb duct and dummy bottom. Therefore, the slurry in the tank will cycle upward and downward in a fixed flow manner, which is helpful to the suspension of those coarse particles. Air and slurry are naturally sucked without need for foam pump. Besides, mine impeller flotation machine for the self-absorption air flotation machine mechanical agitation for non-ferrous metals ferrous metals non-metallic minerals such as sorting.

Main structure:

1. This is mechanical mixing flotation machine by the impeller.

2. The machine is mainly made up by filling slurry chute, mixing device, inflatable device, the device of discharging mineralized bladder, motor etc.

(1)The filling slurry chute: It has the feeding mouth and strobe device for adjusting the surface of mine slurry .It is made up by chute of jointing by armor plate and strobe of jointing by round steel.

(2)The mixing device :It is used for mixing mine slurry to prevent the mine sand deposits at the bottom of chute .It is made up by strap wheel ,impeller ,upright axis etc, impeller is made of wearable rubber.

(3)The inflatable device: It is made up by pipe and inflatable pipe .When impeller is turning, impeller cavity brings negative pressure ,which makes the air suck into by the empty pump and distributes in mine slurry to form the bladder .The mine slurry with bladder is thrown to stator by the turn force of impeller and makes bladder that in the mine slurry fine further and avoids the turn movement of mine slurry stream that in the chute ,produces lots of raising upright micro bladder and provides the necessity condition for flotation .

(4)The device of discharging mineralized bladder: it scrapes the bladder that floats on the surface of the chute and is mainly made up by reducer, scrape board.

Working principle:

When the mine is grinding or after grinding, add water and necessary medicine produces the mine slurry after mixing, feed into the chute that begin to mix, add air into mine slurry to produce lots of bladder .The mine that not easily wet by water attaches the bladder and float to the surface of mine slurry together to produce the mineralized bladder floor .And the rest leaves in the mine slurry and discharges the mineralize bladder to reach the concentrating purpose.

Features and Benefits:

1. Large inspiratory capacity, low power consumption;

2. Air and slurry are naturally sucked without need for foam pump;

3. Allocated horizontally is easy for changing the flow, reasonable circulation, and maximum reduction of the coarse sand aeration;

4. Automatic control device and convenient adjustment.

The use and maintenance of flotation machine:

1. The capacity and time limit of flotation machine depends on the maintenance and keeping every main assembly works normally, every part should be examined once every 3to 4months .In the first months of works, should be examined often.

2. Only the skilled worker can examine the machine.

3. In order to change the assembly in time, should store whole set of easily destroyed assembly .The quantity and time of use depends on the fact use.

4. Only the skilled worker can operate the machine.

5. To prevent the swag, adding the oil should have the filter .When the flotation machine works, the oil cover should be sealed.

6. Before staring, should contact with other every procedures.

7. Starting order: press strobe switch, and the start button.

8. After starting, forbid to touch the rotary part.

Main Technical Parameters:SF Series:

| Model |

Volume(m³) |

Size of tank (L×W×H) (mm) |

Impeller Dia. (mm) |

Impeller speed(r/min) |

Capacity(m³/min) |

Motor power(kw) |

Air flow sucked (m³/㎡min) |

Weight of singe tank(kg) |

| SF-0.15 |

0.15 |

500×500×600 |

200 |

536 |

0.06-0.18 |

1.5/0.55 |

0.8-1 |

269 |

| SF-0.37 |

0.37 |

700×700×750 |

296 |

386 |

0.2-0.4 |

1.5/0.55 |

0.8-1 |

468 |

| SF-0.7 |

0.7 |

820×900×950 |

350 |

400 |

0.3-0.9 |

3/1.1 |

0.8-1 |

805 |

| SF-1.2 |

1.2 |

1100×1100×1100 |

450 |

312 |

0.6-1.2 |

5.5/1.1 |

1-1.2 |

1373 |

| SF-2.8 |

2.8 |

1700×1600×1150 |

550 |

268 |

1.5-3.5 |

11/1.5 |

1-1.2 |

2138 |

| SF-4 |

4 |

1850×2050×1200 |

650 |

220 |

2--4 |

15/1.5 |

1-1.2 |

2582 |

| SF-8 |

8 |

2200×2900×1400 |

760 |

191 |

4--8 |

30/1.5 |

0.9-1 |

4129 |

| SF-10 |

10 |

2200×2900×1700 |

760 |

191 |

5--10 |

30/1.5 |

0.9-1 |

4486 |

| SF-16 |

16 |

2850×3800×1700 |

760 |

191 |

5--16 |

30×2/1.5 |

0.9-1 |

8320 |

| SF-20 |

20 |

2850×3800×2000 |

760 |

191 |

5--20 |

30×2/1.5 |

0.9-1 |

9828 |

KYF Series:

| Model |

Size of tank (mm) |

Single effective volume(kg) |

Effective volume(m³) |

Capacity(m³/min) |

Motor of main shaft |

Impeller |

Motor of scraper |

Wind pressure of blower (kpa) |

| Power(kw) |

Dia.(mm) |

Power(kw) |

| KYF-1 |

1000×1000×1100 |

826.31 |

1 |

0.2-1 |

4 |

340 |

1.1 |

≥12.6 |

| KYF-2 |

1300×1300×1250 |

1419 |

2 |

0.4-2 |

5.5 |

410 |

1.1 |

≥14.7 |

| KYF-3 |

1600×1600×1400 |

1885 |

3 |

0.6-3 |

7.5 |

480 |

1.5 |

≥19.8 |

| KYF-4 |

1800×1800×1500 |

2206 |

4 |

1.2-4 |

11 |

550 |

1.5 |

≥19.8 |

| KYF-8 |

2200×2200×1950 |

3600 |

8 |

3-8 |

15 |

630 |

1.5 |

≥21.6 |

| KYF-16 |

2800×2800×2400 |

5900 |

16 |

4-16 |

30 |

740 |

1.5 |

≥25.5 |

| KYF-24 |

3100×3100×2900 |

7500 |

24 |

4-24 |

30 |

800 |

1.5 |

≥30.4 |

| KYF-38 |

3600×360×3400 |

10300 |

38 |

10-38 |

37 |

880 |

1.5 |

≥34.3 |

Shanghai Sievo Rotary Kiln Equipments Manufacturer, Our product range covers a variety of industries such as Flotation Machine,Flotation Machine Manufacturers,Flotation Machines,Flotation Mineral Processing, all kinds of Flotation Machine,Flotation Machine Manufacturers,Flotation Machines,Flotation Mineral Processing and other items.

If you want this machine(

Flotation Machine),please fill in the form below,or that with our customer service online,thank you!